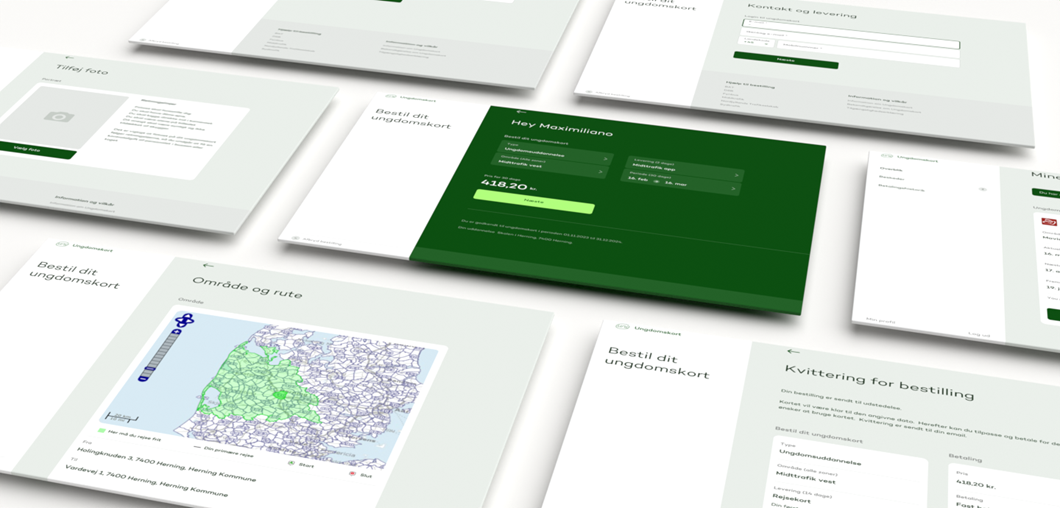

Mit Ungdomskort - New design and user journey

Rejsekort & Rejseplan A/S and the transport service organisations wanted to make it easier for young people and students to order their ‘Mit Ungdomskort’. Together, we have launched a new design and user journey that has simplified the ordering flow and significantly improved the customer experience.

More selected clients

Want to improve your digital business?

Let's talk